Featured

SHIELD SIGHTS - The Latest Red Dot Sight from Shield Sights - The RMSx (Reflex Mini-Sight XL Lens) Glass Edition + FREE BATTERIES FOR LIFE

Introducing The RMSx (Reflex Mini-Sight XL Lens) Glass Edition Buy Any Shield Sight from us and g..

CAM PRO CFP .357 REVOLVER BULLETS - LEAD SAFE - .38 Special &. .357 Magnum .357" Calibre by CAMPRO in CANADA

CAM PRO BULLETS - LEAD SAFE - .38 Special &. .357 Magnum .357" Calibre Bags of 500 ( Als..

AMG COMMANDER Acoustic Shot Timer for IPSC Timed Discipline Shooting - LED or OLED Models

IN STOCK NOW - Same day UK Dispatch AMG COMMANDER Shot Timer for IPSC Shooting - Compact, ergo..

THROOM 4" / 6" / 8" KNOCKDOWN Plate Rack Kit

The THROOM 4" / 6" / 8" KNOCKDOWN Plate Rack Kit includes 6 KNOCKDOWN Targets, 6 KNOCKDOWN Base Moun..

KleenBore - 12 Bore Gauge Shotgun Classic Cleaning Kit - SHO216 Made in USA

SHO216 SKU: 026249000212 12 Gauge Shotgun Classic Clea..

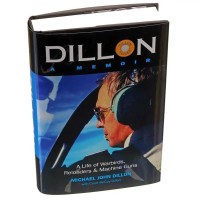

DILLON BOOK - A Memoir - The Mike Dillon Story

DILLON: A Memoir - The Mike Dillon Story A Life of Warbirds, Reloaders & Machine Guns By Michael J..

Special Pie Big Board LED Display with Wireless Connectivity to IPSC Practical Shooting Shot Timer

M16P1 Big board display is a large LED Display Board that can be wireless connected to M1A2 shot tim..

Rollsizer - DC Compact Electric Rollsizer

DC Compact Electric Rollsizer The DC Electric Drive Rollsizer is suitable for the low t..

RELOAD SWISS - RS14 - NEW - Rifle & Pistol Propellant Powder - Minimal bulk density, low energy content and high vivacity, for reduced loads - Collect only

COLLECT ONLY WITH VALID UK AUTHORITY Please Note - All Reload Swiss Propellant Powders are in Sto..

GECO COATED COMPETITION SLUG RED 28g 12/67,5mm per 100 - IN STOCK NOW

GECO COATED COMPETITION SLUG RED 28 12/67,5 Plenty in stock just no mail order - in person transa..

IPSC MICRO 40% CARDBOARD TARGETS WHITE BACK BOTH SIDES HAVE SCORING LINES - 100 PACK

A pack of 100 pieces, top quality, MICRO (40% size) IPSC cardboard targets, with well mark..

CED/DAA Waterproof Target Patches Pasters - Buff / White / Black

The CED/DAA Waterproof Target Patches are designed for ALL-WEATHER conditions. Perfect for com..